While intrinsic material properties such as tensile strength, impact resistance, and thermal stability are critical, optimizing the surface can add a new layer of functionality and improve these already essential features. That is where Lohtragon® comes in, offering a range of products specifically designed for chemical surface treatments like metal pickling, aluminium etching, and electroplating.

Lohtragon® O20 – Ferric Ammonium Oxalate

An excellent candidate for controlled oxidation and surface preparation, this Iron(III)-based salt supports:

By combining ferric ions with oxalate complexation, Lohtragon® O20 enables redox-active surface interactions that are both functional and visually effective.

Lohtragon® V04 – Ferrous Sulfate / Lohtragon® V28 – Ferric Sulfates

Used in acid etching and pickling formulations, these salts help remove surface oxides and deposits left by alkaline degreasing steps - crucial for thin coatings (<140 μm) as found in aerospace or automotive aluminium components.

Use Cases:

Complexing agents such as:

These complexing agents are ideal for buffering, pH control, and controlled interaction with aluminium surfaces - ensuring uniform, reproducible results in multi-metal systems or when minimizing attack on specific aluminium alloys.

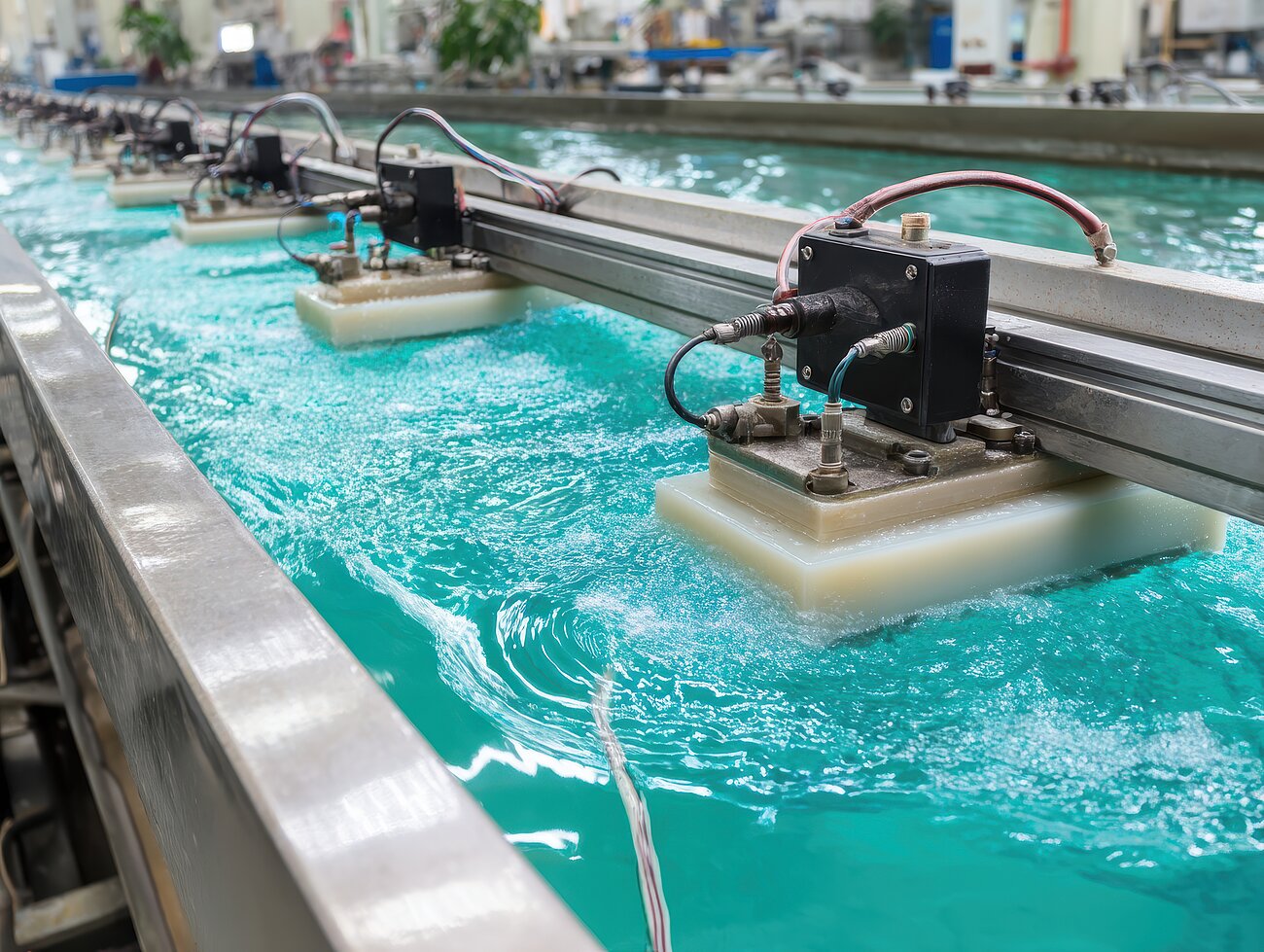

Aluminium’s popularity across industries - from aerospace and automotive to electronics and packaging - is rooted in its low weight, corrosion resistance, and versatile surface properties. But to ensure consistent coating, bonding, coloring, or corrosion resistance, the aluminium surface must be pre-treated and modified using precise chemical methods.

Lohtragon® products support aluminium surface treatment with customized metal salts, if desired developed in close collaboration with your technical teams.

We do not only sell pre-packaged solutions - we help you create them.

Our metal salt-based developments apply to a broad range of aluminium treatments, including:

Each use case requires specific chemistry, bath design, and compatibility checks - your expertise supported by our team of Lohtragon® metal salt specialists.

As regulatory pressures phase out toxic and environmentally harmful components such as chromates or nitrates, Lohtragon® helps you develop greener alternatives using:

At Lohtragon®, we do not only offer standardized aluminium surface treatment products. Instead, we provide:

Our goal is to design application-specific additive systems that meet your technical, regulatory, and sustainability requirements.

Do you need an optimized, sustainable pickling system? Looking to replace critical ingredients? Or want to explore the use of iron salts for functional oxidation?

Get in touch with our Lohtragon® experts to discuss your needs.

Iron

Ammonium

Potassium

Sodium

Sample Request

Product Finder

Contact